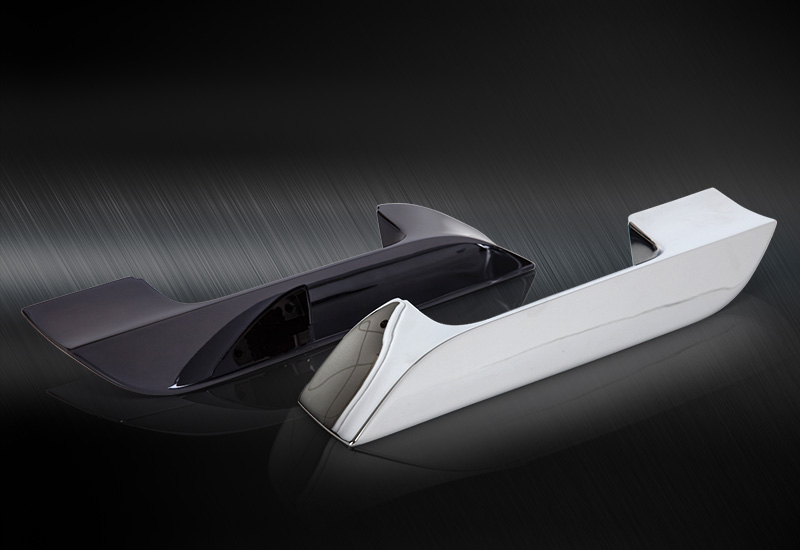

Part Manufacturing

Complete capabilities

From production parts to manufacturing aids, we use advanced technology to keep production moving. We’ve invested significantly in our people, facilities and technology to serve as a single source for complete electroplated parts. Parts may be produced in an affiliated Non-AS9100 certified facility.

QCP’s advanced manufacturing and finishing services are ideal for both market introductions and limited production runs. When your design has been tested and perfected, we can easily ramp up to full production. Our capabilities are as vast as your new ideas.

- Vacuum forming

- Injection molding

- SLA production

- Soft tool casting

- CNC machining

You’ll save on shipping, paperwork and staff time by cutting one purchase order for a complete electroplated part. Send us your print with requirements and we’ll provide a quote. It’s that simple.

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.

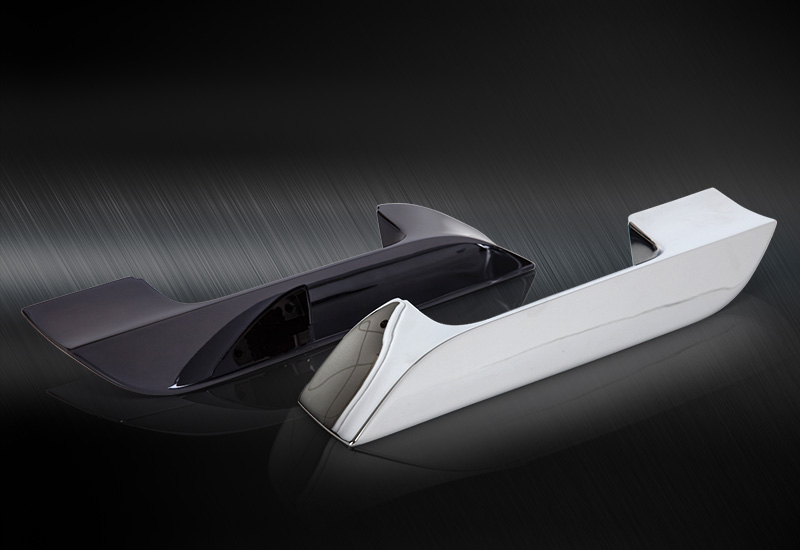

Complete capabilities

From production parts to manufacturing aids, we use advanced technology to keep production moving. We’ve invested significantly in our people, facilities and technology to serve as a single source for complete electroplated parts. Parts may be produced in an affiliated Non-AS9100 certified facility.

QCP’s advanced manufacturing and finishing services are ideal for both market introductions and limited production runs. When your design has been tested and perfected, we can easily ramp up to full production. Our capabilities are as vast as your new ideas.

- Vacuum forming

- Injection molding

- SLA production

- Soft tool casting

- CNC machining

You’ll save on shipping, paperwork and staff time by cutting one purchase order for a complete electroplated part. Send us your print with requirements and we’ll provide a quote. It’s that simple.

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.