Commercial Finishing

Craftsmanship, quality and experience

QCP is widely recognized for its unmatched decorative plating services and capabilities – serving both the industrial and commercial markets. We meet the rapidly changing requirements of our global customers through research, new technologies and expanded capacity.

Do you design or manufacture parts or high-performance machines requiring decorative finishes? QCP combines distinction, quality and style to outperform expectations. We’ve provided solutions to Tesla, Ford, GM, Honda, International Game Technology, Performance Machine and other leading companies.

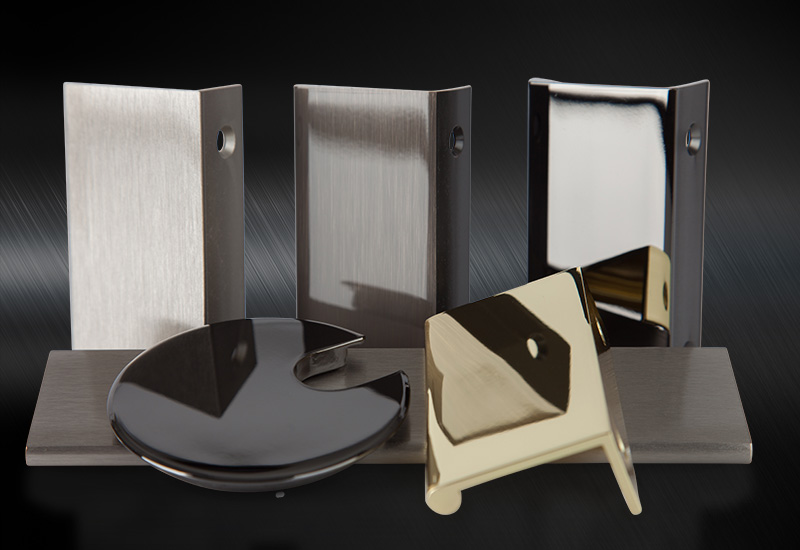

Turning functionality into beauty

With a complete range of services and over 100 finishes available, we can plate hundreds of metal and plastic substrates. Typical applications include lighting fixtures, faucets, furniture, door hardware and other applications.

- Multiple facilities & flexible capacity

- Largest tank sizes

- Documentation (PFEMA, FEMA, Control Plans)

- Incoming inspections & AQL audits

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.

Craftsmanship, quality and experience

QCP is widely recognized for its unmatched decorative plating services and capabilities – serving both the industrial and commercial markets. We meet the rapidly changing requirements of our global customers through research, new technologies and expanded capacity.

Do you design or manufacture parts or high-performance machines requiring decorative finishes? QCP combines distinction, quality and style to outperform expectations. We’ve provided solutions to Tesla, Ford, GM, Honda, International Game Technology, Performance Machine and other leading companies.

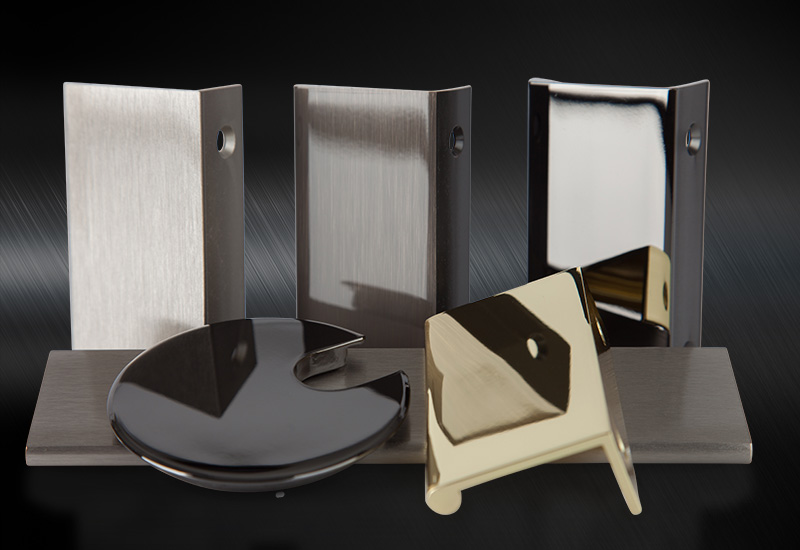

Turning functionality into beauty

With a complete range of services and over 100 finishes available, we can plate hundreds of metal and plastic substrates. Typical applications include lighting fixtures, faucets, furniture, door hardware and other applications.

- Multiple facilities & flexible capacity

- Largest tank sizes

- Documentation (PFEMA, FEMA, Control Plans)

- Incoming inspections & AQL audits

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.